The bicycle is a self-explanatory machine. Almost every part of it is there to be seen at a glance. So it's all too easy to neglect or underestimate the hidden ball bearings which keep the moving parts on the move.In any mechanical device, where two bearing surfaces make frictional contact with each other, some means must be found of minimising the friction.

In many cases, a well-lubricated "plain" bearing will do the job, especially if the bush is of phosphor-bronze or some similar hard alloy. In the more advanced

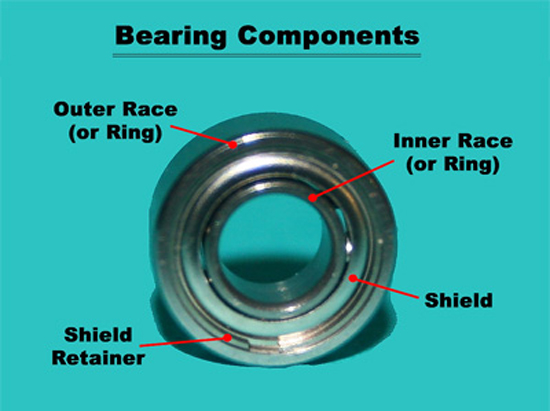

"ball" bearing, however, the load or thrust is borne by a number of hardened alloy-steel balls which are themselves free to move along a narrow circular channel or "race." In a theoretically

ideal ball-bearing, the load is concentrated at areas which are merely points. The steel balls are theoretically perfect spheres and therefore make direct contact with the opposing surfaces at two points, reducing the area liable to frictional wear to an absolute minimum. Also, as the balls themselves are of a specially-hardened steel and are free to move in a rolling manner, any slight amount of wear which they undergo during the course of time will be equalised over the entire surfaces of the balls. The balls, therefore, may ultimately become slightly reduced in size, but they will all be reduced equally; and thus they will keep their spherical shape, so that the working efficiency of the ball bearing is maintained.

In practice, ball-bearings are not perfect in their proportions, and signs of wear occur after a time. A theoretically perfect

ball bearing would need no lubrication at all. Since it is impossible to manufacture absolutely spherical hardened steel balls, a true rolling motion of the balls within their race cannot be guaranteed; and the ball-race itself is always slightly concave - this concavity increasing with wear. So commercial ball-bearings must be lubricated.

*All

ball-bearings in a bicycle should be dismantled and examined at the minimum once a year. Twice a year is much better. If the balls have not been adequately lubricated they will be worn sharp or rough, with small pits or depressions in the surfaces of the races. The best thing to do with such an article is to chuck it out.

Generally speaking, the balls themselves are the first to show signs of wear, and replacing them, with new balls will be enough to make the bearing like new. But the slightest sign of pitting in a hub-cone, or a crown-race, or a bracket-cup, should mean its instant relegation to the dust bin. Fitting new balls to worn races will simply ensure the rapid destruction of yet another set of balls.It sometimes happens that a ball will crack, breaking up into small fragments. Generally, this fault is detected soon after it has occurred; particularly if the cracking has taken place in the head-assembly or the bracket-interiors.

Do not merely replace the defective ball with a new one. Replace ALL the balls in that race. This makes sure that all the balls in the race are of uniform size. If a new ball has a slightly larger diameter than the old worn balls it will have to bear a far greater share of the load. It will come under excessive strain, probably resulting in a repeat performance of the original trouble!Dirt and dust are great enemies of ball bearings and if not kept out of the

bearing, will set up friction between the individual balls in the race, preventing them from rolling freely. "Sticking" and "sliding" will result; this erratic behaviour will soon wear depressions into the race and will gradually destroy the entire bearing. This is why the efficiency of the hub dust-caps or other covering, should be carefully maintained.

The best lubricant for a ball-bearing consists of a medium-thin grease, filling the hubs, bracket, and head, with the excess wiped away after assembly. Pedals and (some) gear-pulleys are also fitted with ball-bearings, so don't forget these usually neglected items.The steel balls will thus become covered with a thin layer of lubricant which will not only reduce frictional wear at their points of contact within the race, but will also minimise the inevitable friction between the balls themselves.If you have any doubt as to the number of balls to put into a race, simply fill it and then remove one ball. The number of balls should NEVER be over-estimated; it would be better to under-estimate. An over-filled race will always jam -sooner or later. Similarly, it is the lesser of two faults if a bearing is slightly loose, rather than even fractionally tight.

One big thing has changed though; twenty odd years ago most cycle components had no significant bearing seals. They relied heavily on the water resistance of the grease itself to keep the water out. It was only the invention of the mountain bike and people riding through muddy puddles up to their axles which forced component manufacturers to significantly improve the quality of their seals. As a result, modern quality cycle parts don't need re-greasing every six months. Many in fact are sealed for life and we are seeing more and more sealed

cartridge bearings being specced as standard equipment.

ARB Bearings Limited H-22, Udyog Nagar

New Delhi - 110041, Delhi, India

Phone: +(91)-(11)-25471274 / 25471255 / 25186300

Fax: +(91)-(11)-25475455 / 25470126

Email: info@arb-bearings.com,

export@arb-bearings.com,

sales@arb-bearings.com For Export Enquiry :

Mr. Divay Rathee : +91-9968373086Website: http://arb-bearings.com/contact-us.php